Our Technology Fleet

At Modern Duct Factory, we believe superior quality begins with tool precision. Therefore, the heart of our facility is a comprehensive fleet of the latest CNC machinery and integrated automatic production lines. This strategic investment guarantees that complex engineering designs are translated into products with absolute dimensional consistency, achieving the highest production efficiency and the lowest possible air leakage rates.

Duct Auto Line

The Duct Auto Line represents a transformative leap in manufacturing efficiency, functioning as a fully integrated system that converts raw sheet metal into complete duct sections with minimal human intervention. The process starts with automatic coil feeding, followed sequentially by leveling, notching, shearing, and hydraulic edge forming (such as TDF or TDC flanges). The machine operates with maximum synchronized speed and precision, ensuring unwavering consistency in quality and dimensions across all high volume duct pieces. This compact line not only reduces production time and labor costs but also ensures that the duct edges are immediately installation ready, drastically accelerating the on site assembly process and minimizing potential errors.

Spiral Round Duct

The Spiral Round Duct Machine is a highly specialized tool dedicated to producing circular air ducts with exceptional efficiency and superior quality, favored in many applications for their benefits related to ease of installation and low pressure loss. This machine operates by helically winding a galvanized metal strip and interlocking the edges to create a tight, rigid, and leak resistant seam along the length of the duct. It is characterized by its ability to produce various diameters and lengths with high precision, ensuring the internal duct wall is smooth and uniform, which is crucial for reducing air flow noise and optimizing the ventilation system’s efficiency.

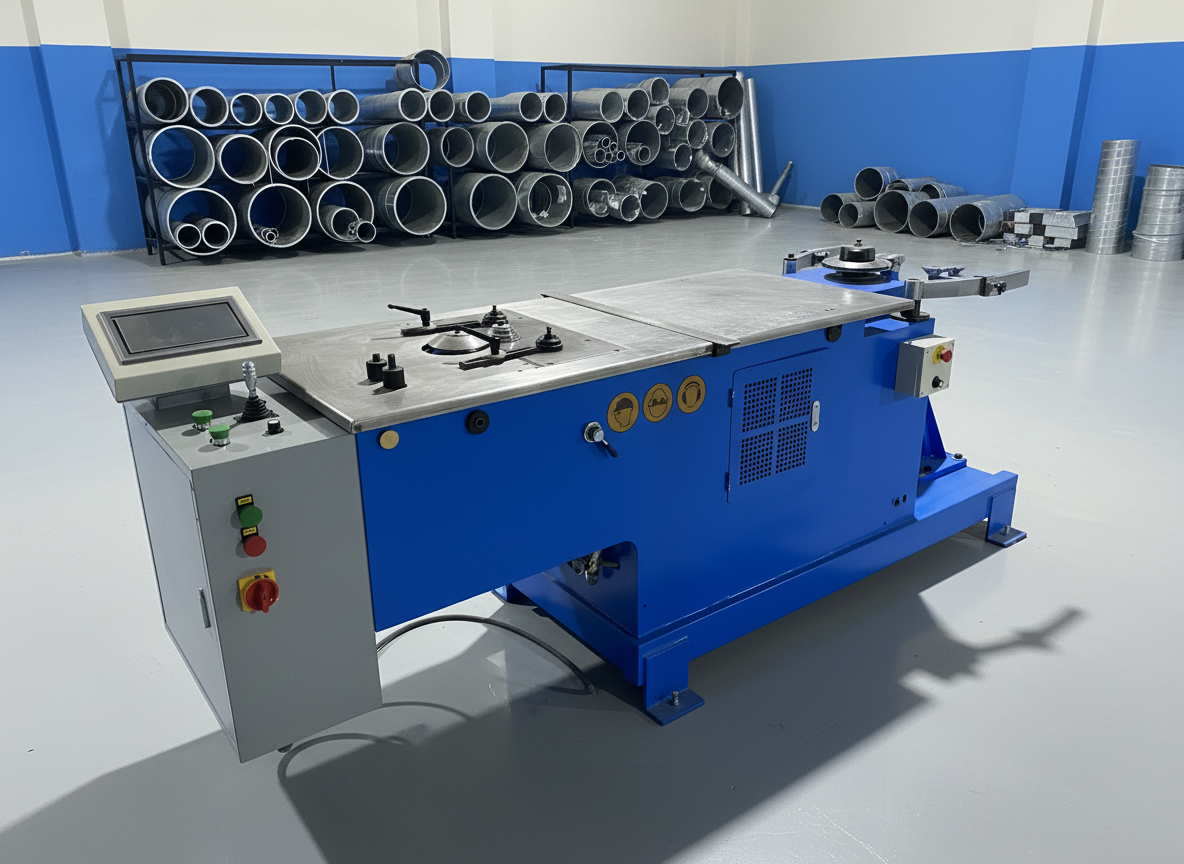

Hydraulic Elbow Making

Hydraulic Elbow Making Machine is essential for the precise and efficient production of curved circular HVAC duct components. Its significance lies in its ability to accurately form and assemble the gore sections of elbows, ensuring that required angles (such as 90 or 45) are perfectly shaped to minimize air flow resistance within the system. The hydraulic system provides immense and controllable force, allowing it to handle various sheet metal thicknesses to produce elbows with a strong, tightly sealed seam. This reduces turbulence and pressure loss within the duct, thereby enhancing the overall aerodynamic efficiency of the HVAC system and extending its operational life.

CNC Plasma Cutiing

Plasma Cutting Machine is the cornerstone of a modern HVAC duct manufacturing line, ensuring the achievement of the highest standards in engineering precision and operational efficiency. Operating with an advanced Computer Numerical Control (CNC) system, this machine accurately translates complex geometric designs (such as elbows and transitions) into perfect cutting paths on the metal sheets. This results in clean and sharp cuts with minimal “dross” formation, significantly reducing the need for subsequent cleaning and preparation processes. Utilizing a 63A power source, it offers the capability to process various sheet metal thicknesses required for HVAC duct standards with superior speed and efficiency. This guarantees absolute component consistency, which is a prerequisite for minimizing air gaps and thus improving the overall efficiency of the HVAC system while substantially reducing material waste

TDC Flange

The TDC Flange Machine is an indispensable component in high quality rectangular duct production, specializing in forming an integrated flange system directly onto the edge of the duct sheet. The (TDC) system eliminates the need for separate corner pieces and frame components, significantly reducing time and cost. This machine ensures that the flange is formed with absolute precision to be perfectly symmetrical, which greatly simplifies the on-site duct assembly process and guarantees a strong, air-tight mechanical joint. The result is quick to install duct connections with excellent leak resistance, enhancing the overall efficiency of the Heating, Ventilation, and Air Conditioning (HVAC) system.